Plastics extrusion is a high-volume longitudinal product manufacturing process in which raw plastic is melted and formed into a continuous profile. Extrusion produces items such as pipe/tubing, weather stripping, fencing, deck railings, window frames, plastic films and sheeting, thermoplastic coatings, and wire insulation. This process starts by feeding plastic material (pellets, granules, flakes or powders) from a hopper into the barrel of the extruder.

The material is gradually melted by the mechanical energy generated by turning screws and by heaters arranged along the barrel. The molten polymer is then forced into a die, which shapes the polymer into a pipe/profile/sheet that hardens during cooling at lower temperature. At final end, longitudinal shapes are trimmed and cut-to-length as per requirement.

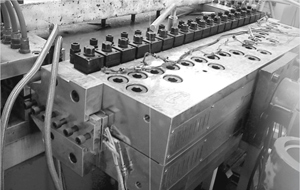

T Die technology is a sheet manufacturing device where molten plastic is taking shape as per the internal design and lips fixed on the mouth. T die on the back is fixed on the extruder head. Sometimes it is fixed with the distributor device where co-extruders are attached for multi-layer sheet manufacturing.

T die is heated with external heaters for supporting the flow of plastic melt inside. T die is prolonged with calibration molds to form a sheet with certain thickness. Cooling and curing of melt takes place into calibration molds. Lips fixed on the Die head decides about the thickness range of the plastic sheet.